Freighters Induction

Freighters Induction

Freighters Induction

Download PDF version below

Freighters Induction and Truck Loading Procedure

All freighters must complete an Induction prior to commencing work on Baines Masonry’s site.

As a visitor/contractor to Baines Masonry you are required to adhere to Baines Masonry’s Policies and Procedures. These Policies and Procedures

are put in place in order to maintain a safe, healthy and friendly workplace.

The procedures are available in Baines Masonry’s office for your referral.

Adherence to Baines Masonry’s Drug and Alcohol Policy may involve you being screened for substances as per our Policy.

All freighters must attend the office upon arrival and sign out at the yard office upon leaving. All work to be carried out must be discussed

with the relevant Baines Masonry employee prior to commencing and presented to the relevant employee for inspection prior to completion.

Freighters must wear the following in all areas:

- Hi – Vis Vest or Shirt

- Steel Capped Boots/Shoes

- Hearing and eye protection where signposted or required

All work is to be carried out in conjunction with all WH&S legislation, Baines Masonry’s Policies and Procedures and any laws governing your

work practices.

Basic Emergency Response Procedures

A Guide for Contractors

In case of an emergency or evacuation:

You will report to the Evacuation Warden in your work area. Wardens’ are identified on the Emergency Control Organisation Hierarchy of Control

which is posted around the workplace. In the case of an Emergency the Warden in the area will make themselves clearly recognisable.

All directions given by Baines Masonry Evacuation Wardens must be followed for your own safety

In the case of Evacuation:

When your Area Warden receives the order to evacuate from the Chief Warden (or Acting Chief Warden) they will instruct you to:

- REMAIN CALM, DO NOT PANIC

- MOVE IN AN ORDERLY FASHION

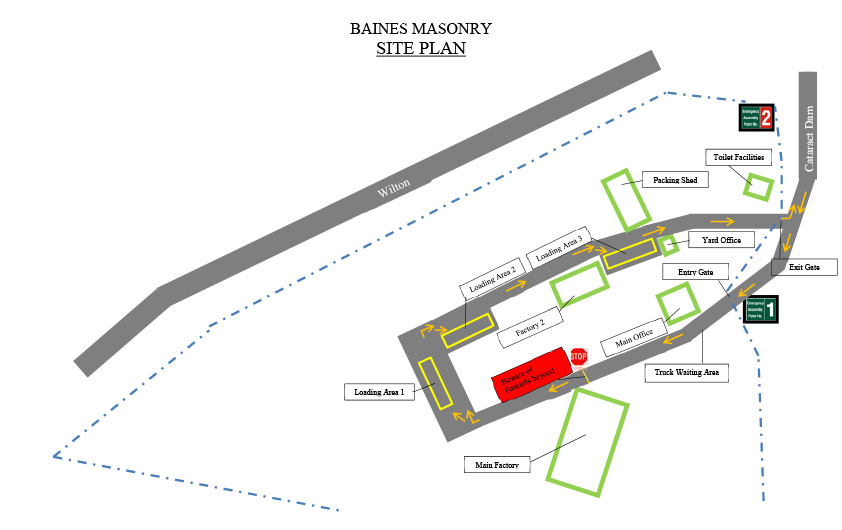

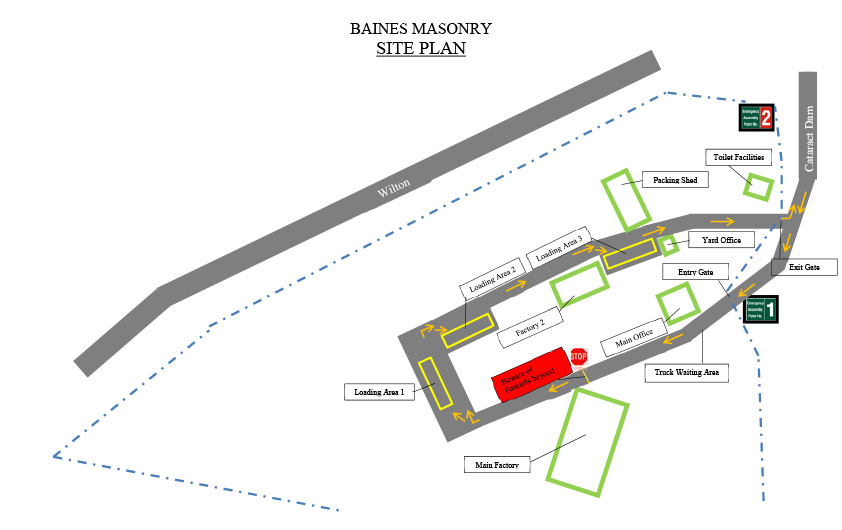

- MOVE DIRECTLY TO THE NOMINATED “EMERGENCY ASSEMBLY POINT” This is located:

• At this sign outside the main office car park gate ->

• Or at this sign located on Wilton Rd & Cataract Rd Corner ->

- DO NOT RETURN TO THE WORK AREA OR YOUR VEHICLE

- REMAIN AT THE “EMERGENCY ASSEMBLY POINT” UNTIL THE CHIEF WARDEN INSTRUCTS YOU OTHERWISE.

Truck Loading / Unloading Procedure

PURPOSE

To ensure safe & efficient loading and unloading of vehicles with a minimum gross vehicle mass of 4.5 tonnes at the Baines Masonry Appin site.

SCOPE

This is for the loading of products (non-bulky goods) on trucks to be delivered to desired destinations and to the unloading of vehicles (non-bulky

goods). This pertains to the yard department of Baines Masonry Blocks.

This procedure should be used in conjunction with the;

• Goods Receipt Procedure

• Purchase Order Procedure

• Order Picking and Packing Procedure

EQUIPMENT AND PERSONAL PROTECTIVE EQUIPMENT USED

PPE:

Hi Vis garment

Steel Cap Boots or Shoes

Equipment:

Forklift

Load Restraining Equipment

Heavy Vehicles

PPE must be worn prior to entering Baines Masonry premises.

Truck drivers must be aware of all signage onsite pertaining to speed limits, stop signs, give way signs and any other applicable signage,

Forklifts have right of way on our site, please travel slowly in our yard to avoid any possible near miss.

ACTIONS (Loading Vehicles)

The following procedure explains the steps to follow:

Trucks are not permitted to proceed past the Main Office until direct by yard supervisor or office staff. Yard Supervisor can be contacted

on UHF9. In the absence of the Yard Supervisor a Leading hand will fulfill his duties for the purpose of this procedure.

- Access to yard:

i. Dedicated Contractor: Maintain 5 km/h speed limit, follow directions of Yard Supervisor as to what loading area

to park in.

ii. Outside Contractor: Not permitted enter before 7.00am or after 3.30pm. Enter yard at 5 km/h speed limit

and report to office to receive delivery dockets and direction. Check contractor is wearing PPE as per this procedure.

- The Driver needs to complete Pre-Loading declaration at the at the Main office prior to loading (copy included). Drivers and vehicles should

be inducted prior to presenting for pickup.

- The driver should confirm they have sufficient angles and straps to secure their load as per the Baines Masonry Safe Load Requirements.

They should check that the load legally suits the Mass and Dimension Limits of the vehicle they are driving.

- If insufficient restraining equipment is available it can be purchased from our office or we can modify the delivery docket to only load

what can be restrained with the available equipment.

- If the load does not meet the Mass and Dimension Limits of the vehicle then the delivery docket can be modified to suit the vehicle.

- Once directed, proceed to requested truck loading area 1, 2 or 3. (See attached Map)

- Driver to attend Yard Supervisors Office for direction, then proceed to requested truck loading area 1, 2 or 3. (See attached Map)

- Park in loading area as directed by forklift operator.

- Disembark truck, open gates and prepare truck for loading.

- Place any previously completed delivery dockets in the tray provided on the Yard Supervisors Desk. Discuss with forklift operator how you require the truck to be loaded ensuring you comply with Safe Load Requirements with regard to mass and distribution of load.

- The truck driver must remain inside, in front of or beside the truck cab whilst being loaded / unloaded and must stay in view of the forklift driver at all times.

- When truck is loaded, the forklift driver parks, and informs truck driver the loading has finished.

- Truck driver and forklift driver both check load & discuss any issues/questions about how the truck is loaded.

- If anything has to be moved or replaced return to step 5 to step 7 until both parties are satisfied with how the vehicle is loaded.

- Driver then ties down and secures load as per the NTC Australia “Load Restraint Guide Second Edition 2004” or they can follow the Baines Masonry Load Restraint Guide available of main office.

- Once satisfactorily tied down, driver must then have the load and restraints checked by the Yard Supervisor and the driver must sign out on the digital Dispatch Register prior to leaving the yard, to confirm that they are compliant with the HVNL and CoR regulations.

- If driver needs to attend other business after this time they should park their truck out the front or down driveway, so as not to hold up other trucks that may be waiting to be loaded. Drivers should attend to all paperwork etc. at steps 2-5 where possible.

Actions (Unloading Vehicles)

The following procedure explains the steps to follow:

Trucks are not permitted past the Main Office until direct by yard supervisor or office staff. Yard Supervisor can be contacted on UHF9.

- Access to yard:

i. Dedicated Contractor: Maintain 5 km/h speed limit, follow directions of Yard Supervisor as to what loading area

to park in.

ii. Outside Contractor: Not permitted enter before 7.00am or after 3.30pm. Enter yard at 5 km/h speed limit

and report to office to receive delivery dockets and direction. Check contractor is wearing PPE as per this procedure.

- Driver to attend Yard Supervisors Office for direction, then proceed to requested truck loading area 1, 2 or 3. (See attached Map)

- Park in loading area as directed by Yard Supervisor.

- Disembark truck, open gates and prepare truck for unloading.

- Place any previously completed delivery dockets in the tray provided on the Yard Supervisors Desk. Instruct yard supervisor where the products on the truck are from.

- The truck driver must remain inside, in front of or beside the truck cab whilst being loaded / unloaded and must stay in view of the forklift driver at all times.

- When truck is unloaded, the forklift driver parks, and discusses with truck driver his requirements or paperwork before leaving. If truck now requires Loading, refer to Loading Procedures (above).

- Driver then ties down and secures load as per the NTC Australia “Load Restraint Guide Second Edition 2004” or they can follow the Baines Masonry Load Restraint Guide available of main office.

- Once satisfactorily tied down, driver must then leave the yard to ensure a flow of heavy vehicles through the yard is maintained.

- If driver needs to attend other business after this time they should park their truck out the front or down driveway, so as not to hold up other trucks that may be waiting to be loaded. Drivers should attend to all paperwork etc. at step 5 where possible.

Freighter Induction Acknowledgement

• I understand the terms of my induction.

• I understand and will follow the Basic Emergency Response Procedures.

• I understand and will follow the Loading and Unloading Procedure

• I will ensure all work carried out is of a high standard complying with all relevant legislation.

Name: _________________________________

Licence No:: _________________________________

Company: _________________________________

Date: _________________________________

Freighter Inductions have a 12 month expiry date.