HEXABASE™

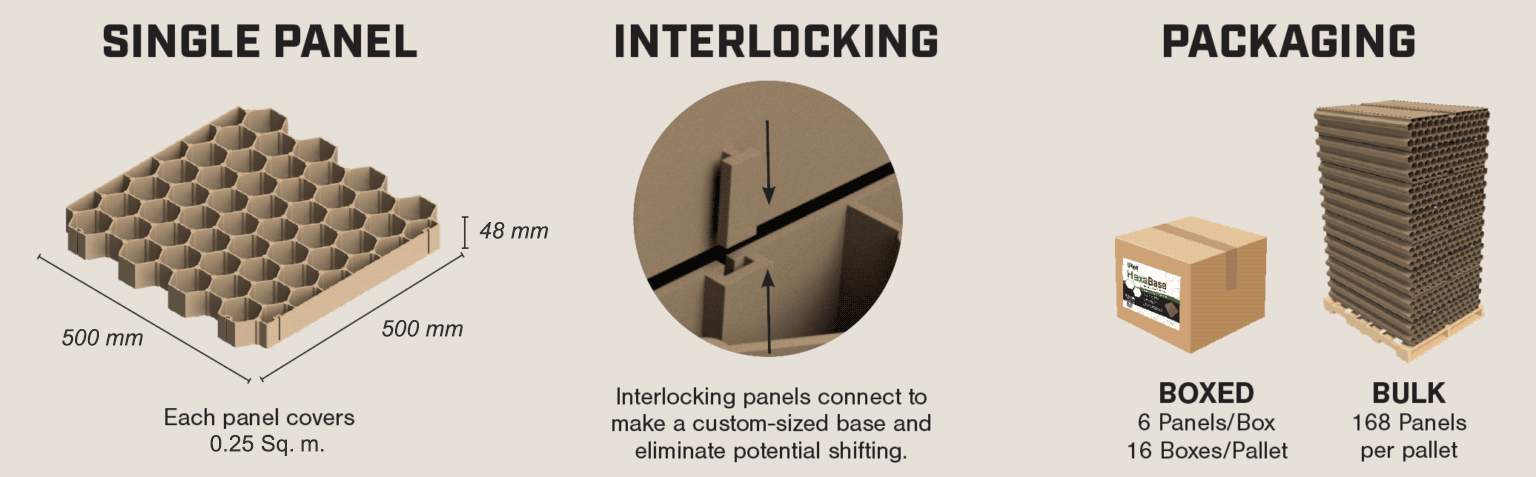

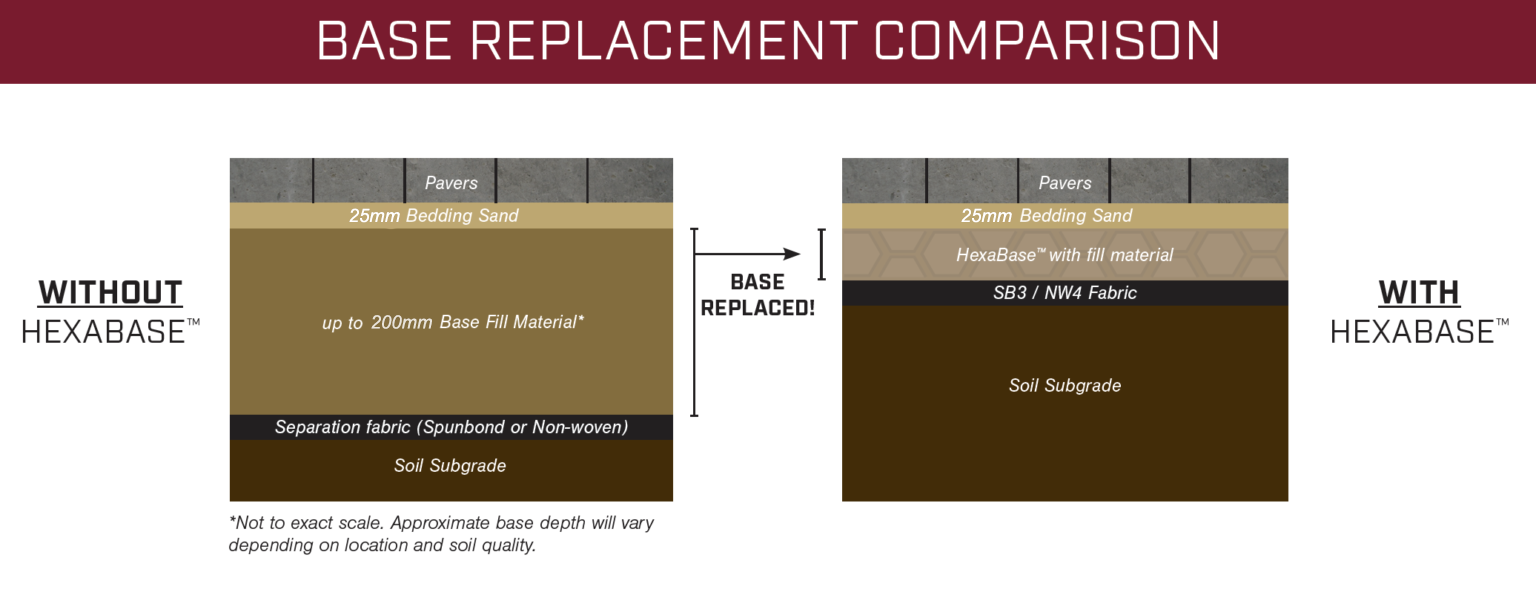

3-in-1 Reinforcement

Base Replacement

- Follows industry installation standards.

- Reduce costs of fill material and excavation.

- Replace 150mm - 200mm of base in paver projects.

- 100% Permeable

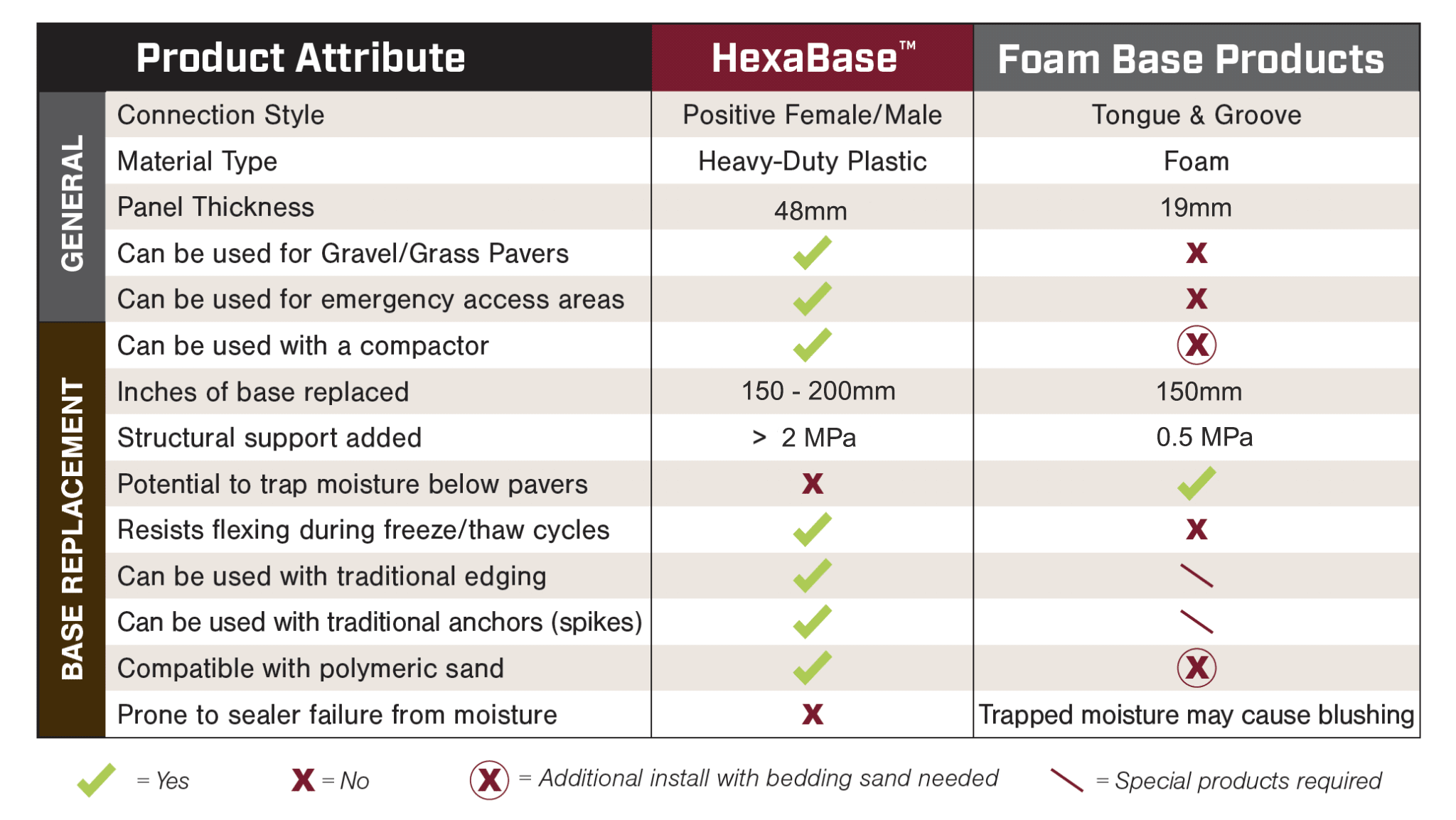

- 30x stronger than foam base panels.

- No special accessories needed.

Grass/Gravel Pavers

- Lightweight & easy to install.

- No special tools required.

- Provides temporary or overflow parking while keeping the look of a lawn.

- Plush lawn look with the structural rigidity of an aggregate base.

- Great for trails for golf carts and utility vehicles.

Fire Apparatus Lanes

- Can be used in fire lane applications as an aesthetically pleasing alternative to gravel.

- Add base structure to emergency vehicle access lanes.

- Review local municipality building codes prior to use.

Ready to purchase?

Dealers/Distributors: Contact our Customer Service Team, at Baines Masonry to place an order.

Contractors & Homeowners: Contact Us to find out where you can purchase our products!

Instructions

For Grass Paver Installation Instructions, See the HexaBase Technical Data Sheet.

PAVER APPLICATIONS:

MINIMUM EXCAVATION

A. Survey out the area where the patio or walkway will go. The overall size of excavation will be 6" larger

on each side than the final paved project, except along structures or foundations.

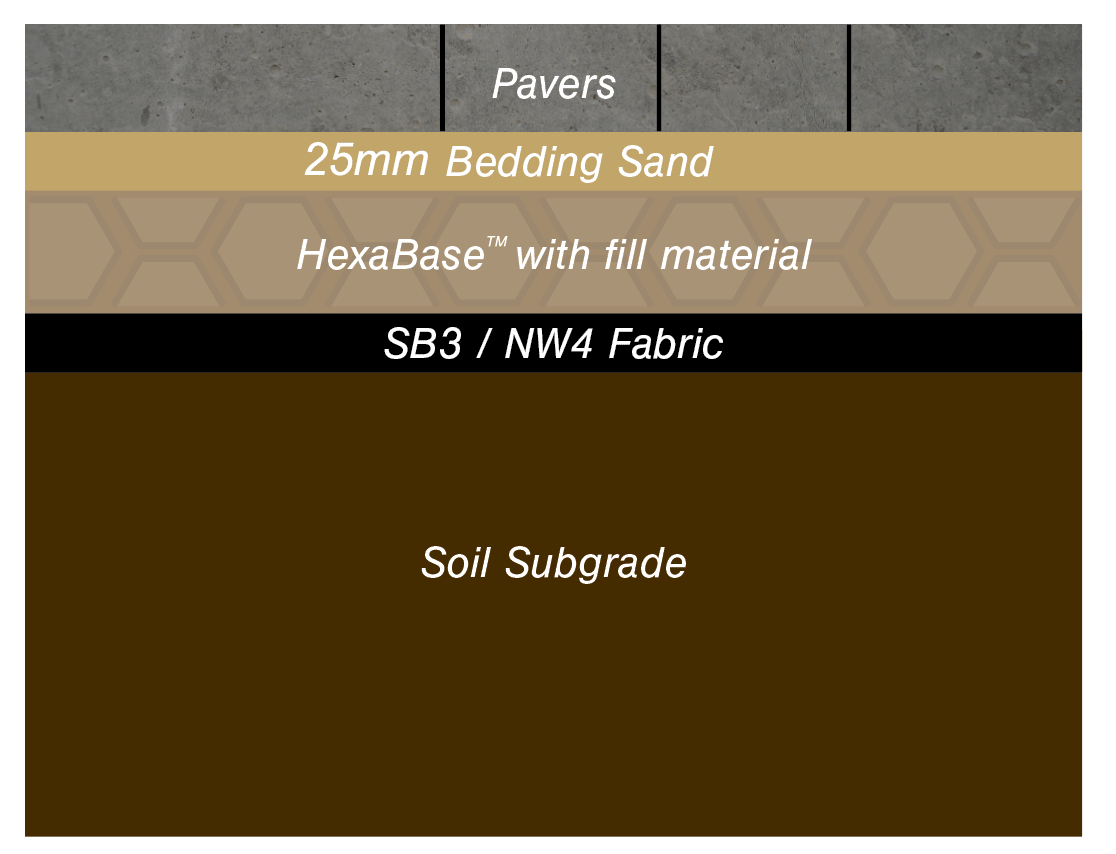

B. Total excavation depth will be determined by the overall height of the paver or chosen surface. To calculate the depth needed, simply add 65mm to the thickness of the paving materials (pavers, natural stone, wetcast, etc.). This measurement takes into consideration the thickness of the Hexabase panels and the 25mm layer of bedding sand (bedding sand will compact to approximately 15 – 20mm after paver installation is complete)

C. Excavate area to the total depth calculated above, ensuring the area remains flat and properly sloped for water drainage away from structures.

PRODUCT TIP: For a long-lasting installation, excavated area should be as flat as possible and free of any roots or large stones that could cause uneven settling over time.

PREPARE THE SOIL SUBGRADE (NATIVE SOIL)

D. Compact Soil Subgrade with overlapping passes using a plate compactor. Be sure to compact perpendicular to the original direction as well. Frequently check the area to ensure the Soil Subgrade remains flat and properly sloped during compaction, raking soil into low areas as needed and re-compacting until satisfied.

PRODUCT TIP: It may be required at times to hydrate the area with a garden hose to allow for proper compaction.

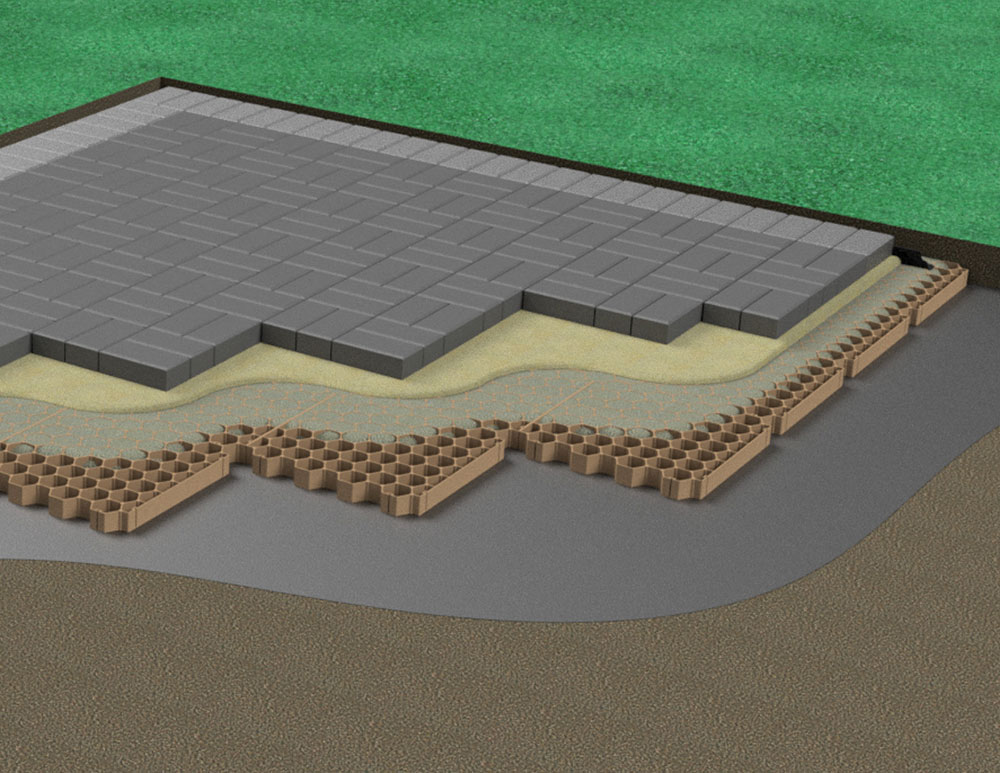

E. Roll out the desired SRW separation fabric (SB3 or NW4) on top of the excavated area, allowing edges to run up the sides 50mm, and overlap 300-450mm at the seams. This layer is crucial to the long-term performance of the system and will keep the Soil Subgrade from migrating into and contaminating the Compacted Aggregate fill material in the HexaBase™ cells.

F. Pull the fabric taught, removing folds or wrinkles, and secure using staples.

INSTALLATION

G. Starting in a corner, lay HexaBase™ panels directly on top of the Separation Fabric, over the entire excavated area. Take care to fully lock each panel to the adjacent panels before continuing on.

H. Trim any panels around the edges to correct size using a handsaw, circular saw or similar tool.

I. Using a permeable, compactable base material (20mm minus, crushed Limestone, Quarry Process Stone, or other equivalent base aggregate), fill the cells of the HexaBase™ slightly over the top of the cell walls (3 – 6mm) uniformly across the area.

J. Use plate compactor in several directions to compact base material into cells. Refill cells

where necessary with base material and repeat compaction until cells are completely full.

K. Place 25mm screed pipes or rails directly on the panels and spread bedding sand over them. Bedding sand under concrete pavers should conform to ASTM C33 OR CSA A23.1.

L. Carefully screed bedding sand using a straight board to a uniform 25mm thickness across entire area.

PRODUCT TIP: Any irregularities or unevenness in the bedding sand will be reflected in the surface of the pavers. It is not recommended to use the bedding sand as a leveling layer, as uneven areas of the bedding sand may settle over time and cause depressions in the paver surface.

M. Install paved surface according to manufacturer recommendations.

EDGING

N. HexaBase™ is specifically designed to use traditional edging products and spikes.

O. Be sure to use 10" smooth or spiral spikes to secure edging around the paved surface.

P. When installing edging, ensure spikes are being driven into aggregate filled cells at least 150mm from the edge of the HexaBase™ panels.

Packaging

HexaBase™ Interlocking Base Replacement

| PART NUMBER | SIZE |

TOTAL SQ M |

QUANTITY |

|---|---|---|---|

|

GSRW HB CTN |

6/CTN |

1.5 |

16 CTNS/PLT |

|

GSRW HB BULK |

1 |

42 |

168 PCS/PLT |

Frequently Asked Questions

Call us on (02) 4631 1383 . We will gladly help locate a supplier near you!